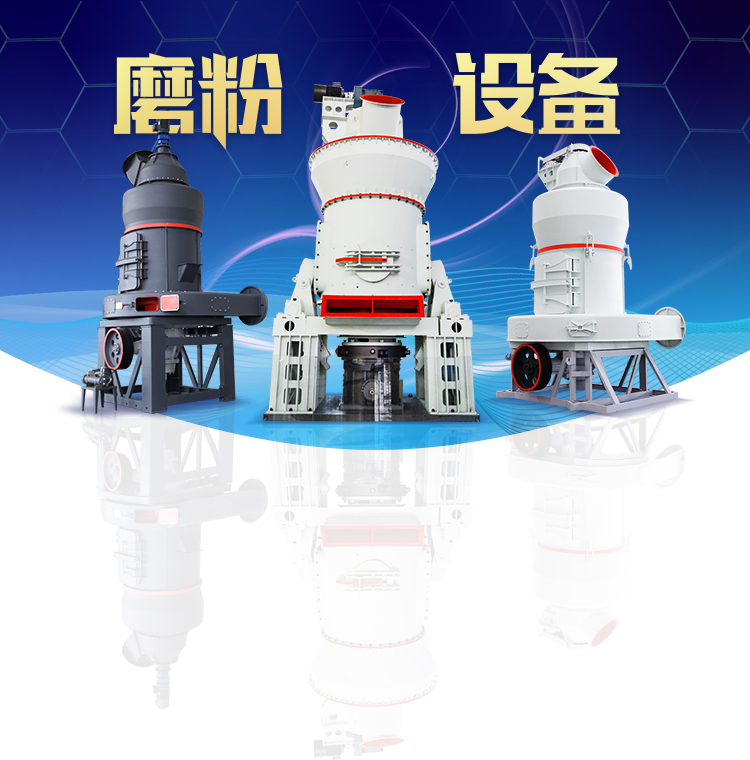

细粉加工设备(20-400目)

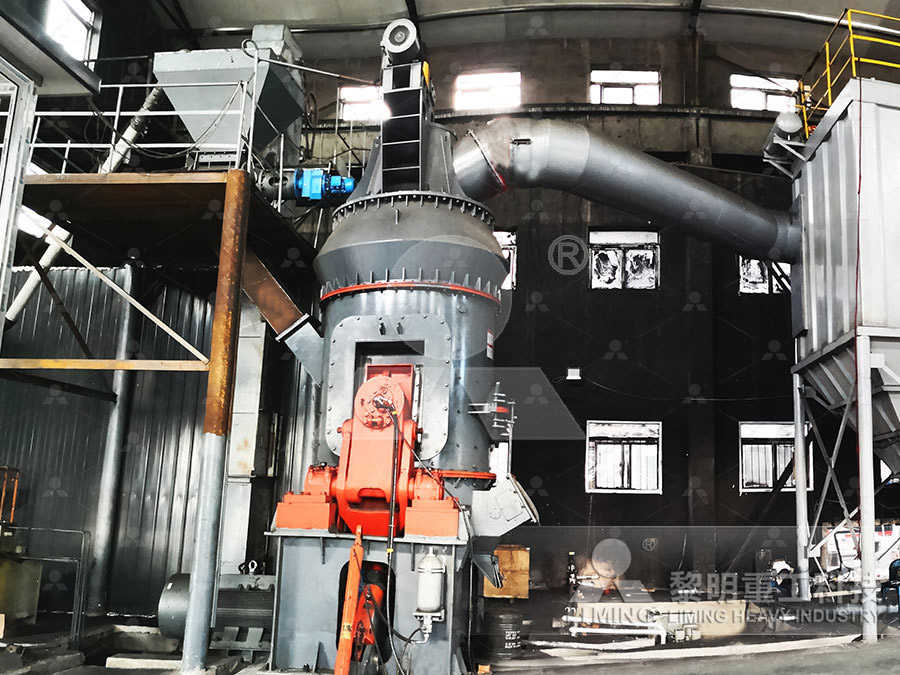

我公司自主研发的MTW欧版磨、LM立式磨等细粉加工设备,拥有多项国家专利,能够将石灰石、方解石、碳酸钙、重晶石、石膏、膨润土等物料研磨至20-400目,是您在电厂脱硫、煤粉制备、重钙加工等工业制粉领域的得力助手。

超细粉加工设备(400-3250目)

LUM超细立磨、MW环辊微粉磨吸收现代工业磨粉技术,专注于400-3250目范围内超细粉磨加工,细度可调可控,突破超细粉加工产能瓶颈,是超细粉加工领域粉磨装备的良好选择。

粗粉加工设备(0-3MM)

兼具磨粉机和破碎机性能优势,产量高、破碎比大、成品率高,在粗粉加工方面成绩斐然。

singlerollcrusher

McLanahan Roll Crushers

Since patenting the first Single Roll Crusher in 1894, McLanahan has become an expert and leader in the industry in the design and manufacture of single and two stage Roll 2023年8月4日 This assures you the ultimate in troublefree operating efficiency, minimum and simplified maintenance and long service life Our Single Roll Crushers are ideal for heavyduty primary and secondary Single Roll Crushers Shredders for Scrap

Single Roll Crushers Mecotra

Single Roll Crushers Pennsylvania Crusher builds three models of single roll crushers: the Hercules, the Atlas, and the Type K The Type K Single Roll Crusher is suited for the size The single roller crusher has a driven roller and a swivelling crushing wall The crushing tools of both units are coordinated so that a defined final grain can be produced The end SRC Single roll Crusher

Roll Crushers ScienceDirect

2016年1月1日 Abstract This chapter deals with the designs and operation of different types of roll crushers Two main types are indicated The first type where the rolls are Typically designed for primary crushing, McLanahan Single Roll Crushers efficiently crush material at a 6:1 crushing ratio They can continually withstand heavyimpact applications Single Roll Crushers reduce large McLanahan Single Roll Crusher Brochure

Single Roll Crushers Acan Machine

Single Roll Crushers are primary crushers that provide a crushing ratio They reduce materials such as coal, mine refuse, shale, slate, gypsum, bauxite, salt, soft shale, etc, from large size particles to a medium size, 2024年4月19日 There are two main types of impact crushers: horizontal shaft impactors (HSI) and vertical shaft impactors (VSI) HSI crushers utilize a horizontal rotor that throws the material on stationary anvils or curtains, which results in the material breaking upon impact VSI crushers, unlike the traditional crushers, have a vertical rotor which Types of Crushers Explained: Everything You Need to Know

Single Roller Crusher Simple And Efficient Crushing

2023年3月11日 Single roller crushers consist of a single cylindrical roller that operates horizontally The roller revolves at low speed and breaks the incoming material against the surface of the roller Depending on the type of roller crusher, the roller may have a smooth, corrugated, or toothed surface to facilitate the crushing process2023年2月20日 In summary, a single roller crusher is a simple and effective machine used for crushing softer materials into smaller pieces It is commonly used in industries such as mining and construction and single roller crusher LinkedIn

Single Roll Crushers Mecotra

The Type K Single Roll Crusher is suited for the size reduction of material having a compression strength of 8,000 psi or less Such materials typically include coal, petroleum coke, lignite and other friable materials The Hercules and Atlas models are suited for materials with higher compressive strength2019年11月21日 A good rule of thumb for singlestage crushers is that a Single Roll Crusher provides up to a 6:1 ratio of reduction and a Double Roll Crusher provides up to a 4:1 ratio of reduction In the event that the application requirement exceeds the guidelines discussed herein, dictating more than one crushing stage, then a determination will have McLanahan Factors to Consider When Selecting the Proper

Roll Crushers Lancaster Products

3 天之前 Lancaster Model 48 x 32 Double Roll Crusher Roll opening: 12″ x 18″ Roll opening: 48″ x 32″ Each roll opening: 24″ x 32“ Drive: 5 HP Drive: 30 HP Capacity: Up to 3 ton/hour Capacity: Up to 60 tons/hour Lancaster Products Roll Crushers reduce – in a single pass material previously requiring primary and secondary crushingHigh throughput crushing Consistent product size Robust design Low maintenance Suitable for soft and mediumhard mineral materials Products Heavyduty, high throughput crushers for the mining industry The Double Roller Crusher is ideal for soft and mediumhard rock applicationsDouble Roll Crusher DRC

McLanahan Quad Roll Crushers

Why McLanahan Quad Roll Crushers By creating one machine to do the work of two, McLanahan has generated a lower overall headroom requirement and a simplified process flow Quad Roll Crushers also feature hydraulic product size adjustment for both the primary and secondary crushing stages This allows producers the option of changing size Single Roll Crusher Brochure Brochures Typically designed for primary crushing, McLanahan Single Roll Crushers efficiently crush material at a 6:1 crushing ratio They can continually withstand heavyimpact applications Single Roll Crushers reduce large size particles in the feed to a medium size, while producing a low percentage of finesMcLanahan Single Roll Crusher Brochure

Roll Crushers ScienceDirect

2016年1月1日 2400 Roll crushers are arbitrarily divided into light and heavy duty crushers The diameters of the light duty crushers vary between 228 and 760 mm with face lengths between 250 and 460 mm The spring pressure for 2011年1月31日 Cobra Single Roll Crusher, all gearing is cut from alloy steel The Cobra Single Roll Crusher utilizes a cast iron gear and an alloy steel pinion gear All McLanahan Single Roll Crushers utilize the Vbelt drive arrangement Electric motor power is transmitted to a grooved and balanced flywheel pulley mounted on the countershaft VSSINGLEINGLE RROLLOLL CCRUSHERSRUSHERS Minspec

Crushers BEUMER Group

5 天之前 Crushers Our product range includes impact, single, double and shear roller crushers as well as continuous roller and hammer crushers FAM designed crushers are used for crushing minerals, raw materials and other bulk commodities The types of crushing machines are distinguished by their working principles: by pressure, impact, hammer, or 2016年2月6日 Single Roll Crusher: American Pulverizer single roll coal crushers are the product of nearly a century of experience Each is designed to the highest engineering and construction materials standardsto assure you the ultimate in troublefree operating efficiency, minimum and simplified maintenance, and long service life Single Roll Crusher DL Williams Company

New insights into double roll crushing ScienceDirect

2023年11月1日 Abstract Double roll crushing is a comminution principle that has already been deployed for more than 100 years It is known for high throughputs of sometimes sticky materials such as overburden However, its applicability for ore and hard rock processing has been underestimated in recent decadesThe DRCDouble roll crusher is designed in such a way that the rollers can be reversed from standstill with extremely high starting torques Foreign objects that cannot be crushed are automatically released from the crushing chamber This is done with the help of the hydraulic gap adjustment, which can open and close the crushing gap fastDRCDouble roll crusher A crusher for all scenarios

Single Roll Crusher Premur Impex Best performing crushers

Single Roll Crusher Single Roll Crusher Application Primary and Secondary crushing of soft nonabrasive or medium abrasive materials like coal, coke, chalk etc, with normal crushing ratio of 4:1 The crushing action takes place by impact of rollteeth against spring loaded breaker plateAdvantages Compact, flat design: Low overall height of crushing plant Easy integration in existing plants Low fines content in the final product: Low dust generation No dedusting system required Roll sizer Discover thyssenkrupp Polysius, where innovation and engineering excellence coexist harmoniously Learn more about our crushing machineRoll sizer thyssenkrupp Polysius Crushing Technologies

Single roll crusher 掌桥科研

2020年8月6日 摘要 Around a single roller crusher, at least one having a motordriven roller (1) rotatably mounted in a crusher housing, with crushing teeth and other breaking means being arranged on the jacket (2) of the roller (1), which protrude over the jacket (2) and are arranged in rows on top of one another follow, with the other crushing means Robust roller crusher and sizer offering to maximise your crushing capabilities Our roller crushers and sizers are built to last, with strong frames and selflubrication systems to reduce your maintenance burdens They offer reliable crushing of materials in the cement and mining industry, including highlyabrasive and sticky ones, and Longlasting roller crusher and sizer solutions I

polysius® crusher thyssenkrupp Polysius Crushing

The thyssenkrupp Impact Crusher produces a single stage perfect feed material for a vertical roller mill They crush mediumhard to hard material Find out more DoubleRollCrusher DoubleRollCrushers are used for the crushing or mediumhard rock as well as for sticky and soft materials, ie clay, marl, limestone and similar raw materialsSingle Roll Crushers are primary crushers that provide a crushing ratio They reduce materials such as coal, mine refuse, shale, slate, gypsum, bauxite, salt, soft shale, etc, from large size particles to a medium size, Single Roll Crushers Acan Machine

Single Roll Crusher Manufacturers and Exporters India

Adding Perfection To The Industrial Processes With Single Roll Crusher Ecoman is one of the top mostpreferred crusher manufacturing, selling and distribution company, which makes efficient and exclusively customized single roll crushers that best suit the special requirements of varied industrial applicationsIf you are interested, please feel free to contact us Email: Phone: +49 (0) 2261 80 47 300 Thanks to our innovative roll crusher technology, we develop high throughput crushers for various areas of applicationsInnovative roll crusher technology Crush + Size Technology

Dynamics in double roll crushers ScienceDirect

2017年4月1日 Abstract Double roll crushers (DRC) have the highest throughputs among primary crushers In the oil sands, the hourly capacity may exceed 14,000 t/h They are preferably used to comminute mediumhard rock or sticky materials An unusual tough particle or unbreakable object may effect substantial dynamic forces in a DRCWhy McLanahan Double Roll Crushers McLanahan Double Roll Crushers feature slower roll speeds and a larger surface area to add prolonged life to the crushing elements, resulting in less maintenance downtime and decreasing your cost per ton Double Roll Crushers generate minimum fines while producing a cubical productMcLanahan Double Roll Crushers

Single Roll Crusher tegamcnally

2023年11月4日 APPLICATION Single Roll Crusher is an ideal primary breaker for crushing ROM coal, soft to hard limestone, ores, etc They can be built in large sizes to handle high capacities and runofmine large lumps OPERATING PRINCIPLE The crushing rings on the rotor crush the material by piercing and pressing the material against the breaker plate2023年9月5日 Get In Touch Address : Plot NoI111112113, Phase IV, GIDC, VUNagar, Anand Gujarat, India Office Phone : 02692 Fax : Roll Crushers Single, Double, Four Roll Crusher

Construction Working and Maintenance of Crushers for

2018年12月26日 For example, a singleroll crusher, employ shear together with impact and compression Shear crushing is normally used under following conditions When material is somewhat friable and has relatively low silica content For primary crushing with a reduction ratio of 6 to 1 When a relatively coarse product is desired, top size usually larger 2020年1月8日 专利类型 发明专利 摘要 【中文】本发明涉及一种单辊筛分破碎机,包括:机壳、电机、减速机、对轮、轴承座、转动辊、破碎板、下料溜板、下料溜子、排铁装置和耐磨盖板。 该破碎机仅有一个辊,并且比原来的双辊破碎机增加了下料溜板、破碎板,以及 【中文】单辊筛分破碎机 【EN】Singleroller screening crusher

McLanahan Triple Roll Crushers

Depending on the duty class, they can be used in most ROM applications, such as coal, salt, lime, pet coke and potash operations Triple Roll Crushers combine a Single Roll Crusher with a Double Roll Crusher to form a crusher that is capable of achieving a 6:1 reduction ratio in the primary stage and a 4:1 reduction in the secondary stage while producing a Single Roll Crusher With Hopper Send us a message to get a call back Contact Us Our goal is to supply bulk materials handling products, services and replacement parts that are safe, troublefree to install, simple to Single Roll Crusher Photos The Young

Capacity Calculations of the Crasher with Stops on a Roll

2022年8月21日 The design has been developed for a singleroll crusher with the forced supply of destroyed material into the crushing zone []The capture of a crushed piece occurs due to the stop located on the roll (see Fig 1); in this case, the condition for formation of a complex stress state in the crushed piece is observed, and the energy consumption is 33″ EXCENCRUSHER Designed to handle the broadest possible range of friable materials, this single roll crusher is engineered for superior performance and reliability The UCC 33” EXCENCRUSHER has been Imperial Crushers UCC Environmental

Roll Crushers (Single Roll Crusher) 45 Manufacturers,

2024年5月21日 For standalone precrushing or integrated in continuous production Typical applications: silo emptying, big bag emptying, material homogenization, preparation stage for fine grinding Technical data Material: 14462; 14404, GMP compliant, max capacity 30t/h, max lump size 280 mm, weight: 360 kg, incl PLC unit3,250 6,550 3,450 6,900 3,650 7,300 1) Crusher capacity calculated based on a typical runofmine feed material with an average raw density 26t/m3 and max feed size less or equal to 80% of crusher feed opening Actual values are depending on feed material characteristics (eg hardness UCS, feed particle size distribution, moisture Eccentric Roll Crusher ERC®

Manufacturing Quality Shredding Reduction Machines

2023年8月4日 RightSize Shredders for Every Application Find the right equipment for the job Videos of our machines in action Sample your materials in our machines Let us know how we can help you American Pulverizer Company designs and manufactures reduction equipment and complete shredding systems for scrap metal, coal, wood, and many other A high productivity and economic operation of the roll crusher combined with increased quality of the final product are the result of consistent development efforts The robust and energyefficient direct drive ensures sufficient power reserves in every application The crushing and drive technology of the Crush + Size double roll crusher DRC Double roll crushers for various application

McLanahan Double Roll Crusher Brochure

Double Roll Crusher Brochure Typically used as secondary or tertiary crushers, McLanahan Double Roll Crushers provide a 4:1 reduction ratio and can be used following other McLanahan equipment, such as FeederBreakers, Rotary Breakers, primary DDCSizers, or Single Roll Crushers, when further reduction of primary crushed material is required2021年1月17日 3780 Mesin stone crusher merupakan sebuah alat yang didesain untuk memecahkan batu dari ukuran besar menjadi ukuran lebih kecil, di Indonesia lebih dikenal dengan sebutan mesin pemecah batu Batubatu yang besar agar dapat dimanfaatkan sebagai campuran dalam pembuatan beton dan aspal Berikut beberapa fungsi dan Mengenal Mesin Stone Crusher Arparts

单辊碎渣机 百度百科

一种炉渣、石块等物品的破碎设备,用于燃煤锅炉除渣系统中使用。该机的电控柜具有卡渣反转功能和自动停机保护功能。其“自控排障”与保护过程是:一旦碎渣机过载卡死,电控柜自动控制碎渣机交替正反转以排除卡阻;若正反转三次仍不能排障,则自动停转电机并发出警报。2024年4月19日 There are two main types of impact crushers: horizontal shaft impactors (HSI) and vertical shaft impactors (VSI) HSI crushers utilize a horizontal rotor that throws the material on stationary anvils or curtains, which results in the material breaking upon impact VSI crushers, unlike the traditional crushers, have a vertical rotor which Types of Crushers Explained: Everything You Need to Know

Single Roller Crusher Simple And Efficient Crushing

2023年3月11日 Single roller crushers consist of a single cylindrical roller that operates horizontally The roller revolves at low speed and breaks the incoming material against the surface of the roller Depending on the type of roller crusher, the roller may have a smooth, corrugated, or toothed surface to facilitate the crushing process2023年2月20日 In summary, a single roller crusher is a simple and effective machine used for crushing softer materials into smaller pieces It is commonly used in industries such as mining and construction and single roller crusher LinkedIn

Single Roll Crushers Mecotra

The Type K Single Roll Crusher is suited for the size reduction of material having a compression strength of 8,000 psi or less Such materials typically include coal, petroleum coke, lignite and other friable materials The Hercules and Atlas models are suited for materials with higher compressive strength2019年11月21日 A good rule of thumb for singlestage crushers is that a Single Roll Crusher provides up to a 6:1 ratio of reduction and a Double Roll Crusher provides up to a 4:1 ratio of reduction In the event that the application requirement exceeds the guidelines discussed herein, dictating more than one crushing stage, then a determination will have McLanahan Factors to Consider When Selecting the Proper

Roll Crushers Lancaster Products

3 天之前 Lancaster Model 48 x 32 Double Roll Crusher Roll opening: 12″ x 18″ Roll opening: 48″ x 32″ Each roll opening: 24″ x 32“ Drive: 5 HP Drive: 30 HP Capacity: Up to 3 ton/hour Capacity: Up to 60 tons/hour Lancaster Products Roll Crushers reduce – in a single pass material previously requiring primary and secondary crushingHigh throughput crushing Consistent product size Robust design Low maintenance Suitable for soft and mediumhard mineral materials Products Heavyduty, high throughput crushers for the mining industry The Double Roller Crusher is ideal for soft and mediumhard rock applicationsDouble Roll Crusher DRC

McLanahan Quad Roll Crushers

Why McLanahan Quad Roll Crushers By creating one machine to do the work of two, McLanahan has generated a lower overall headroom requirement and a simplified process flow Quad Roll Crushers also feature hydraulic product size adjustment for both the primary and secondary crushing stages This allows producers the option of changing size Single Roll Crusher Brochure Brochures Typically designed for primary crushing, McLanahan Single Roll Crushers efficiently crush material at a 6:1 crushing ratio They can continually withstand heavyimpact applications Single Roll Crushers reduce large size particles in the feed to a medium size, while producing a low percentage of finesMcLanahan Single Roll Crusher Brochure

Roll Crushers ScienceDirect

2016年1月1日 2400 Roll crushers are arbitrarily divided into light and heavy duty crushers The diameters of the light duty crushers vary between 228 and 760 mm with face lengths between 250 and 460 mm The spring pressure for

矿山开采业煤耗标准

--如何申请办理沙场

--粉煤灰加工石粉

--RP783中速磨煤机

--旧3.5*13m磨机价格旧3.5*13m磨机价格旧3.5*13m磨机价格

--如何计算河坝磨粉场的生产成本

--内蒙古兴安铬欧版粉碎设备

--石料生产线安全操作规程

--制粉的机器

--中国阿拉伯撒可富复合肥价格

--氧化钙粉碎再利用

--青山矿业采矿证

--梧州粉碎设备黄页梧州粉碎设备黄页梧州粉碎设备黄页

--生产镁砂设备

--宁波在哪可以卖破手机

--线路板石磨机

--上海节能雷蒙磨

--每小时产650T硅石立式石头破

--活性石灰石生产线

--火山灰粉碎机械

--华扬s75立式机

--异形石材加工设备视频

--甘肃宏鼎磨料科技有限公司法人

--高效立式破

--粉碎水泥块设备

--yyp压入式干喷LM立式辊磨机

--球磨机混匀

--石子厂加工设备

--高效无声粉碎剂

--每小时产1200T制粉机

--